Rob Feldman

Rob Feldman, LPed is a Board Certified and Licensed Pedorthist specializing in utilizing orthotics, footwear, and bracing to care for common foot pathologies. Rob identified the need to be sensitive to busy and active lifestyles by creating a one of a kind method to integrate an on-line telehealth evaluation, digital self-scanning, and live guidance through the ordering process. His company, Fore2Feet specializes in custom, semi-custom, and certain pre-fabricated orthotics that are specifically designed for certain activities that the active adult participates in. His Golf and Tennis orthotics are one of a kind and are truly designed for those sports, as are the other lineup of choices. Another distinguishing factor is that Fore2fFeet leverages digital 3-D scanning and 3-D printing to fabricate these specialized and precise orthotics. Click on any of our links to learn about each specialty orthotic that have been utilized by thousands of active adults seeking to ‘stay in the game with balance, support, and comfort .

As Easy and Precise as 1 -2-3D!

Our scanning and specialized app is just the beginning of the process and easy! We have digital 3-D Prototypes for:

- Golf

- Tennis/Pickleball

- Soccer

- Skating/Skiing

- General Foot Health and Prevention of injury

No more messy, untimely, inaccurate, and antiquated foam boxes

The advantages are numerous:

1. Highly Customized Fit

- Precision scanning of the foot (often using 3D scanning or pressure mapping) allows for a perfect anatomical match.

- This ensures better support and alignment, improving comfort and reducing pain more effectively than off-the-shelf inserts.

2. Improved Biomechanics

- Custom 3D-printed orthotics are tailored to address specific gait issues, arch types, and foot abnormalities (e.g., flat feet, plantar fasciitis, overpronation).

- This helps in redistributing pressure, enhancing stability, and reducing fatigue during movement.

3. Faster Turnaround Time

- Once the foot is scanned, the digital-to-print workflow is faster than traditional plaster casting and manual adjustments.

- Orthotics can often be ready in a few days instead of weeks.

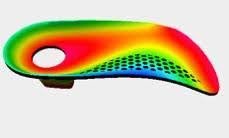

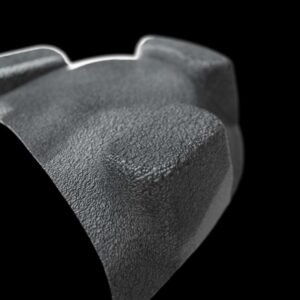

4. Lightweight and Durable Materials

- 3D printing allows the use of advanced materials that are strong, lightweight, and flexible.

- These materials can be customized in terms of stiffness or cushioning in specific zones of the orthotic.

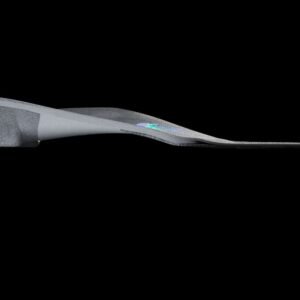

5. Design Flexibility

- 3D printing enables complex geometries and zonal support (e.g., more cushion in the heel, more rigidity in the arch).

- Traditional methods can’t easily replicate this level of structural variation.

6. Eco-Friendly and Less Waste

- Additive manufacturing (3D printing) produces less material waste compared to subtractive methods like cutting or milling.

- Some systems even use recyclable or biodegradable materials.

7. Easier Adjustments and Reprints

- Digital files of the foot scan and orthotic design are stored, allowing for easy tweaks or reprints without starting from scratch.

- Ideal for children or patients whose needs change over time.

8. Improved Patient Compliance

- Because they’re more comfortable, aesthetically pleasing, and fit better in shoes, patients are more likely to wear them consistently.

PRICING

Choose right orthotics for your feet

Select from fully custom, semi-custom, or standard orthotics to match your lifestyle and budget.

CUSTOM

Designed after a thorough telehealth evaluation with design modifications for the even the most difficult foot problems and pathologies like flat feet, Charcot foot, high arches, metatarsalgia, tendinitis, neuropathy, etc.

Evaluation fee applied to the price of the custom orthotic

- Requires 15–20 min telehealth eval (included)

- Exact 3D foot replication from scan

- Delivered in 2–3 weeks

- Available in Golf, Tennis/Pickleball, Lifestyle, Dress Shoe

READYFIT

- No evaluation required

- Built from foot scan, arch height , shoe size

- Available in Golf, Tennis/Pickleball, Lifestyle, Dress Shoe

PERFETTO

- Over-the-counter orthotics

- Effective, budget-friendly, or as an add-on pair

- Standard fit (not custom or semi-custom)

- Not available in Golf/Tennis/Dress prototypes

The Future of Foot Care: Custom 3D Printed Orthotics.

Precision 3D Orthotics: Scanned, Designed, Printed.

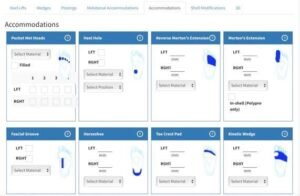

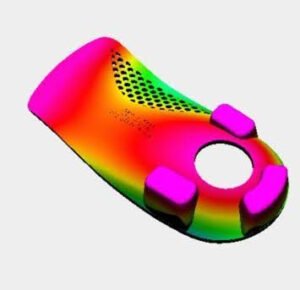

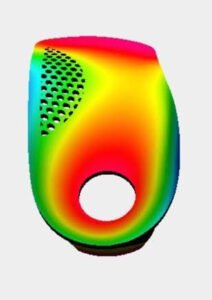

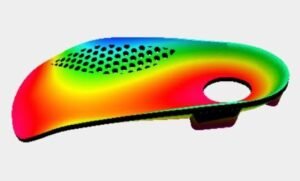

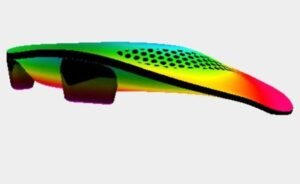

Once we complete your tele-med eval and receive your scan, we then go to work

(1)! We use hundreds of design elements based upon the necessary corrections needed to bring your foot back into balance and out of pain

(2). We then analyze a digital rendering for quality control

(3) It is then sent to the printer to be fabricated in one of the multiple specific prototypes

Sequencing this could look like:

- 1. Scanning of the Foot

- 2. Digital modifications for the patient’s feet

- 3. 3-D Rendering

- 4. Custom Printed Shell

- 5. Voila! Finished Orthotic – Hot Off the Printer and Made for YOUR Feet!